Suncoat Peel (S-Peel), water base peelable coating is a clear, single component, water base temporary peelable protection coating for direct application designed to protection non-

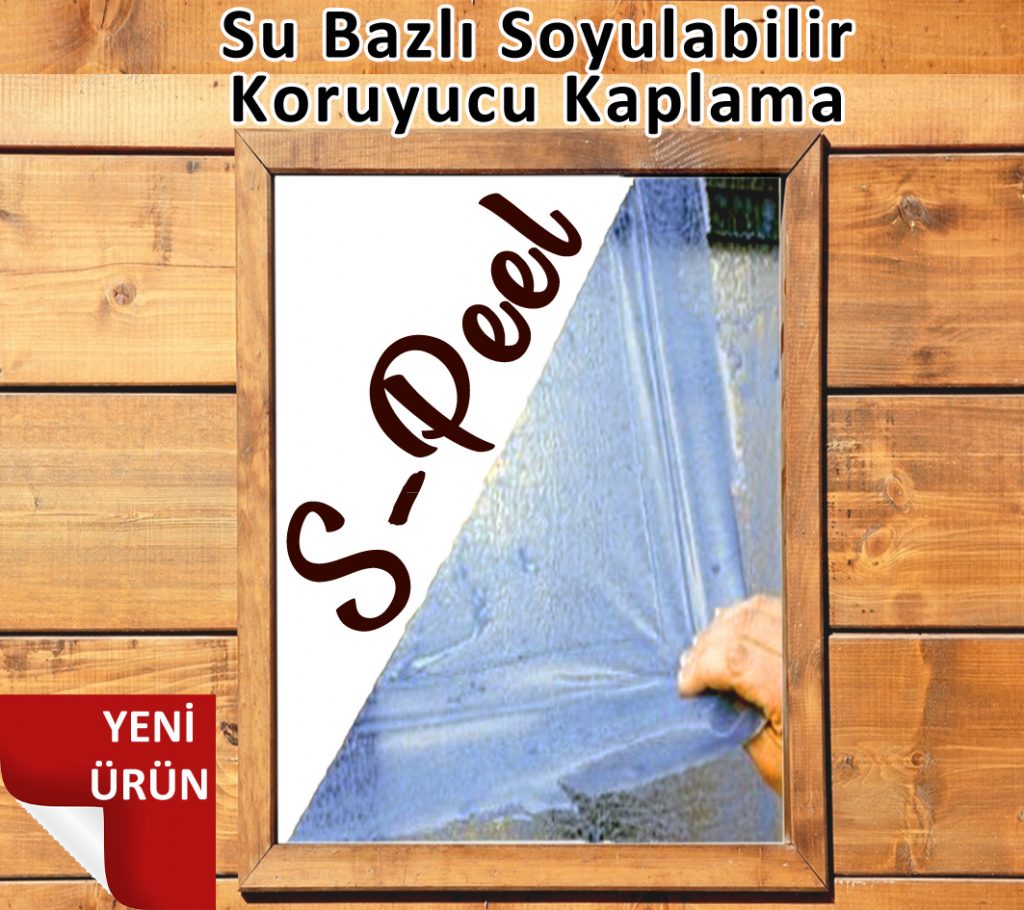

Suncoat Peel (S-Peel), water base peelable coating is a clear, single component, water base temporary peelable protection coating for direct application designed to protection non- porous surfaces from dirt, spills, staining, weathering oil, grease and damages caused by abrasion and scratching.

porous surfaces from dirt, spills, staining, weathering oil, grease and damages caused by abrasion and scratching.

The liquid coating dries to foam a strong waterproofing film that protects surfaces like glass, PVC, aluminum or other metal or non porous surfaces for up-to 18 months. When the protection no longer needed just simply peel off and the protective surfaces will come on as new and clean.

Construction and Architecture Industry: Suncoat Peel protects glass, floor, sink, bath tubes, wooden floor, interior and exterior wall from construction mortar, plaster, paint, welding, heat, UV light, water, damp etc. during construction, renovation/restoration.

Construction and Architecture Industry: Suncoat Peel protects glass, floor, sink, bath tubes, wooden floor, interior and exterior wall from construction mortar, plaster, paint, welding, heat, UV light, water, damp etc. during construction, renovation/restoration.

Aviation Industry: Protects spare parts, all body or glasses of aircarfts / spaceships during manufacture, installation, maintanace, transportation from welding, heat, UV light, water and damp, corrosion etc.

Marine Industry: Protects spare parts, all body, glasses, decks, stairs, fiber or metal parts of yachts/ships during manufacture, installation, maintanace, transportation from welding, heat, UV light, water and damp, corrosion etc.

Otomotive Industry: Protects spare parts, all body, glasses, decks, stairs, fiber or metal parts of all kinds of wheicles including motorbikes, bikes, tractors, trucks and cars during manufacture, installation, maintanace, transportation from welding, heat, UV light, water and damp, corrosion etc.

Otomotive Industry: Protects spare parts, all body, glasses, decks, stairs, fiber or metal parts of all kinds of wheicles including motorbikes, bikes, tractors, trucks and cars during manufacture, installation, maintanace, transportation from welding, heat, UV light, water and damp, corrosion etc.

Material preparation:

Apply the product in temperature range from 15°C – 30°C.

Stir the product well before use.

Features:

Easy to remove

Protect the surface from scratch and other things

High solid content and fast drying

Water base, non hazard, no odour, non toxic

Excellent waterproofing ability

Flexible and zero damage to surface

Application:

Can be applied using roller brush , paint brush or spray gun. Mix properly before use. Always conduct test on test panel of the type of substrate that you intend to use the product on to perform test on application weathering and peel off.

Apply using roller brush or paint brush:

Ensure the surface is dry, clean and free from oil or grease, did the roller brush or paint brush and ensure it completely saturated with the product. Apply the product with minimum wet thickness WFT of 250 microns which yield approx dry film thickness of 100 microns must be achieved. Otherwise removal of fry film will be difficult. Use a wet film gauge to measure the minimum wet film thickness. For best results use 7 inch with thick and long hair paint roller and apply two coats of the product. Allow one coat to dry for 2 hours before applying the second coat.

Apply using spray gun:

Ensure the surface is dry, clean and free from oil and grease. Apply with a 0.43mm tip airless spray gun. Apply the product with minimum wet thickness WFT of 250 microns which yield approx dry film thickness of 100 microns must be achieved. Otherwise removal of fry film will be difficult. Use a wet film gauge to measure the minimum wet film thickness.

Removal: Dry film can be easily removed by peeling off. For best results dry film are best peeled off at 30°C – 40°C. Apply water will further ease the removal process but it is not a requirement.

Storage and shelf life: Shelf life 12 months from the manufacturing date .Storage between 15°C -30°C in a cool dry sheltered place and away from direct sunlight. Donot freeze the product.

Packing: Packing is available in 0,5kg – 1kg – 20kg plastic containers.

Specifications:

Color: Milky White and after applying clear transparent

Nature: water base (Non hazardous)